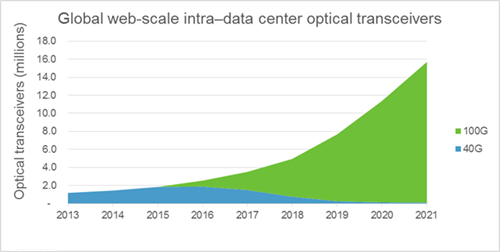

Although most data centers still deploy the 10 Gigabit Ethernet (GbE) networks, the 40/100 GbE networks have gradually become new and preferable options for them, which can be also reflected from the greatly increasing shipments of 40/100G optics. As the data of migration from 10G to 40/100G constantly grow, how to connect the 40/100G device with the existing 10G device in a fast and cost effective manner becomes a particularly vital concern of data center managers. To deal with this issue, experts come up with the MPO pre-terminated optical fiber cabling that is an ideal solution for smooth migration from 10G to 40/100G. In this paper, the breakout panel, a new kind of MPO pre-terminated product, will be studied that facilitates the 10G to 40/100G migration and enables simpler and more efficient network management.

Breakout Panel for 10G to 40G Migration

The breakout panel used for 10G to 40G migration can be referred to as 40G breakout panel or 40G QSFP+ breakout panel, available in both single-mode and multimode versions with the color coded adapters. Just taking the 1RU 40G breakout panel as an example, there are 12 standard MTP connectors (8-fiber) elite to 48 duplex LC connectors, which can build up to 12-group breakout links for the 10G to 40G migration. What’s more, the 40G breakout panel can be designed with up to 96 ports for meeting the high density cabling demands, supporting 480G at most. In short, this kind of breakout panel is a good choice for making a high-performance and reliable straight connection from 10G to 40G.

Breakout Panel for 10G to 100G Migration

We are used to choose the 24-fiber MTP to 10 duplex LC breakout cable to finish the 10G to 100G connection. When it is working, there are 20 fibers in the MTP side to transmit and receive 10G signals and 2 top and bottom fibers on the left and right unused, achieving the 10G to 100G connection. However, there is a serious problem caused if this kind of breakout cable is used for the application, which may increase cable congestion, clutter, tangling and confusion. In order to improve the efficiency and manage the cables better, the breakout panel used for 10G to 100G migration is published with more complicated design than 40G breakout panel. It is fitted with 8 24-MTP (20 fibers used) elite to 80 duplex LC in 1RU panel, which is able to deploy 8 groups of 10G to 100G connections in a simple, efficient and well maintained manner.

Significance of Breakout Panel

The breakout panel combines the advantages of MPO pre-terminated breakout cabling and compact patch panel that can not only solve the cable congestion issue but also save space and cost. Except that, it has various kinds of cabling standards that are available for the 10G to 40/100G migrations. In short, the breakout panel offers a perfect solution for the migration from 10G to 40/100G high density network. To better know the advantages of breakout panel, the following figure illustrates how does a 40G breakout panel work for the 10G to 40G application.

From the figure above, we can learn that the 40G breakout panel is very suitable for the 10G to 40G migration that features MTP interface to connect the 40G QSFP+ module and duplex LC interface to connect the 10G SFP+ module. With the use of 40G breakout panel, the 10G to 40G migration will be easily achieved, greatly meeting the requirements of high density and avoiding the cable congestion issue.

Conclusion

In order to gain higher network speed and larger bandwidth, the 40/100G network market is booming in recent years, which means the cabling network will be more and more complicated. In order to address the cable congestion issue and make the 10G to 40/100G migration in a smooth, efficient and well maintained manner, the 40G and 100 breakout panel are highly suggested. Besides, here offers an article that has more information about the breakout panel solutions.